Parameters of a Solar Cell and Characteristics of a PV Panel

3 days ago · Step by Step Procedure with Calculation & Diagrams. The conversion of sunlight into electricity is determined by various parameters of a solar cell. To understand these

Solar photovoltaic panel specifications dimensions and

The entire process is called the photovoltaic effect, which is why solar panels are also known as photovoltaic panels or PV panels. A typical solar panel contains 60, 72, or 90 individual solar

Dust deposition characteristics on photovoltaic arrays

Jan 10, 2025 · Optimizing the installation parameters of photovoltaic panels in a photovoltaic array to reduce dust accumulation, thereby enhancing their power generation, is a crucial research

Numerical simulation of dust deposition characteristics of photovoltaic

Aug 1, 2024 · Dust deposition on the surfaces of Photovoltaic (PV) arrays during their operation markedly affects their power generation efficiency. Previous resear

PV panel dimensional parameters. Parameter Value [mm]

Among these sources, the use of solar energy is supposed to be considered the main future solution to global climate change and fossil fuel emissions. Since current photovoltaic (PV)

An efficient approach to parameter extraction of photovoltaic

Jun 15, 2024 · This article discusses the problem of accurate and efficient modeling of photovoltaic (PV) panels. It is a highly nonlinear problem. The following mod

Introduction to the parameters models and

What are the parameters of a PV module model? This PV module model has nine parameters: three ideality factors for diodes and the three diode saturation currents, the shunt and series

Precision Modeling and Comparative Analysis of

Apr 29, 2025 · Three steps must be followed to assess the performance of solar PV modules: 5-parameter extraction at STC, modifying the 5-parameters to the necessary environmental

Key Parameters of Solar Panel Data Sheets

Dec 19, 2024 · Dimensions: Panels come in different sizes; standard residential panels are about 1.7m × 1m. Weight: Varies between 18–32 kg for most panels. Make sure the roof or mounting

Electrical, thermal and optical modeling of photovoltaic systems

Feb 1, 2022 · The presented study conducted a substantial literature review regarding the electrical, thermal, and optical modeling of photovoltaic systems. All the

7. Parameters for the Sandia Labs PV Model. | Download Table

Parameters for the Sandia Labs PV Model. from publication: Multiphysics modeling of Photovoltaic panels and Arrays with auxiliary thermal collectors | MultiPhysics Modeling,

Specifications and dimensions of engineering

What are the parameters of photovoltaic panels (PVPS)? ) is necessary for modeling and analysis of solar power systems. The best and the median alues of the main 16 parameters among

PV panel dimensional parameters. Parameter Value [mm]

Parameter Value [mm] Opt. Value Parameter Values [mm] Opt. Value Parameter Values [mm] Opt. Value from publication: The Design Value for Recycling End-of-Life Photovoltaic Panels |

Template for for the Jurnal Teknologi

Abstract- The focus of this study is to develop a computer program that simulates the thermal performance of a photovoltaic (PV) panel. A detailed thermal model of a solar PV panel in

Calculation of Seven Photovoltaic Cells Parameters Using

Dec 11, 2020 · Lately, the researchers are using the two-diode model to determine the photovoltaic cells parameters, especially for the monocrystalline and polycrystalline silicon

Dimensional drawings of photovoltaic panels installed in

The significance of this study is that the proposed approach alleviates the challenges in accurately assessing rural solar PV potential posed by the lack of 3D building models. The determined

Three-dimensional thermal modeling of a photovoltaic

Sep 1, 2012 · Development of three dimensional numerical models to predict PV panel performance. Sequential coupling of radiation and electrical models with 3D thermal model.

Coupled electrical–thermal modeling of photovoltaic

Oct 1, 2024 · The current study reviews thermal, electrical, and coupled modeling of solar systems, emphasizing the prediction of photovoltaic system behavior. All

6 FAQs about [Dimensional parameters of photovoltaic panels]

What are the parameters of photovoltaic panels (PVPS)?

Parameters of photovoltaic panels (PVPs) is necessary for modeling and analysis of solar power systems. The best and the median values of the main 16 parameters among 1300 PVPs were identified. The results obtained help to quickly and visually assess a given PVP (including a new one) in relation to the existing ones.

What are solar panel datasheet specifications?

Key Takeaways of Solar Panel Datasheet Specifications Solar panel datasheet specifications include factors such as power output, efficiency, voltage, current, and temperature coefficient, which determine the performance and suitability of the panel for specific applications.

Do photovoltaic panels need data analysis?

The lack of extensive data analysis on existing photovoltaic panels (PVPs) can lead to missed opportunities and benefits when optimizing photovoltaic power plant (PVPP) deployment solutions. The feasibility study of the PVPP requires accurate data on PVPs in order to fully unleash their potential.

What is an example of a solar panel datasheet?

An example of a solar panel datasheet composed of wafer-type PV cells is shown in Figure 1. Notice that the datasheet is divided into several sections: electrical data, mechanical data, I-V curve, tested operating conditions, warranties and certifications, and mechanical dimensions.

What are the parameters of a solar cell?

The solar cell parameters are as follows; Short circuit current is the maximum current produced by the solar cell, it is measured in ampere (A) or milli-ampere (mA). As can be seen from table 1 and figure 2 that the open-circuit voltage is zero when the cell is producing maximum current (ISC = 0.65 A).

What determines the growth of photovoltaic panel (PvP) production?

The growth of the PVPP market determines the growth of photovoltaic panel (PVP) production. However, in each case, it is necessary to investigate the efficiency of PVPs and the overall performance of the systems in order to select the best PVPs for installation in a specific geographic location.

Learn More

- Are photovoltaic solar panels good for you

- Does the heating of photovoltaic panels affect power generation

- 16 550w photovoltaic panels output voltage

- Avaru Photovoltaic Rooftop Photovoltaic Panels

- Suntec Photovoltaic Solar Panels

- How many solar photovoltaic panels are there in one set

- Photovoltaic containerless solar panels

- Price for individual photovoltaic panels to access the grid

- The price of new photovoltaic panels in Marseille

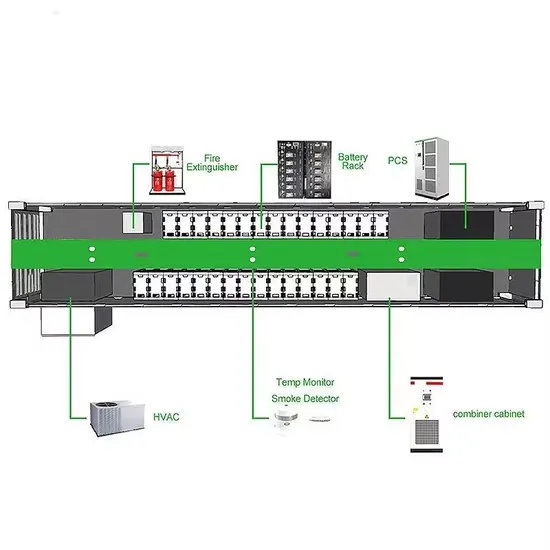

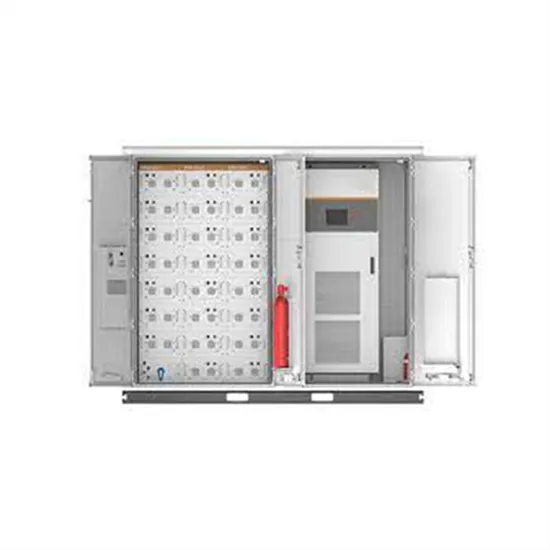

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.