Battery cabinet battery internal resistance 19 milliohms

Battery cabinet battery internal resistance 19 milliohms What is a good internal resistance for a battery? Generally,a lower internal resistance indicates a healthier battery. For example,a

How Internal Resistance Impacts Lithium Battery Efficiency

May 30, 2025 · In lithium-ion batteries, internal resistance is typically measured in milliohms (mΩ) and comprises two components: 1.Ohmic Resistance: Arises from the resistance of conductive

Battery internal resistance – comprehensive analysis and

Mar 20, 2025 · Battery internal resistance refers to the resistance of the battery to the flow of current. It includes the combined resistance of components such as battery materials,

Lithium battery internal resistance capacity comparison

is the typical internal resistance of a lithium-ion battery? The typical internal resistance of a li hium-ion battery varies depending on its capacity and design. G nerally, it ranges from a few

Battery Internal Resistance: Lithium & LiFePO4

Jan 29, 2024 · Lithium-ion battery internal resistance is critical in determining battery performance, efficiency, and lifespan. Understanding what it is, how to

Internal Resistance of a Battery: How to Measure

Aug 29, 2024 · What is Battery Internal Resistance? Battery internal resistance is a crucial parameter that determines the performance and efficiency of a

What is Battery Internal Resistance?

Feb 1, 2025 · Battery internal resistance is the opposition to the flow of current within a battery, caused by its chemical composition, electrode materials, and design. High internal resistance

Battery Heat Power Loss Calculator

The unit for power is watts. Usually the internal resistance of a lithium ion battery is just a few milliohms. The best batteries will have the lowest internal resistance, as the lower the internal

building pack unsure what is high internal resistance 18650

May 10, 2020 · Jonisingt35r said: hello im building a 12s9p 18650 pack for a skateboard i have teted all my cells but unsure what is high internal resistance ? have lots of 18650s and want to

List of standardized internal resistances

Mar 24, 2009 · Maybe you''ve heard, but bearing has come up with a formula for directly calculating a comparable form of internal resistance which basically means you can directly

How to calculate the internal resistance of the battery

Battery internal resistance is a crucial parameter that determines the performance and efficiency of a battery. It is the measure of opposition to the flow of current within the battery due to

Solved: UPS Battery Resistance

Jun 29, 2021 · Battery manufacturers (some but not all) usually quote the internal resistance (more correctly termed "Impedance") for their batteries as "brand new, fully charged", and for a

Battery Internal Resistance: Lithium & LiFePO4

Jan 29, 2024 · Lithium-ion battery internal resistance affects performance. Learn its factors, calculation, and impact on battery use for better efficiency and

Internal Resistance of a Battery | Ossila

Internal resistance is a key indicator of a battery''s performance, closely linked to both its state of charge (SoC) and state of health (SoH). Because a battery''s capacity determines its

Research on Calculating the Internal Resistance of

Jun 28, 2024 · This article takes the Panasonic NCR18650B battery cell as an example, proposes a circuit model and calculation formula for calculating the internal resistance of the battery cell,

The internal resistance of a HV battery block as displayed on

Jan 25, 2024 · The internal resistance of a HV (high voltage) battery block, as displayed on a scan tool, should be A. 15-40 milliohms. Internal resistance refers to the opposition to the flow of

How to measure a battery''s internal resistance with a battery

This technique can be used to measure internal resistance as low as several milliohms. These battery testers also deliver high-precision DC voltage measurement (OCV), another condition

LFP battery internal resistance test method

Aug 30, 2022 · Various problems that are prone to occur in the use of lithium iron phosphate batteries are often reflected in the increase of internal resistance.

What is Internal Resistance? Definition, Principles, and

Jul 20, 2025 · Discover what internal resistance means in lithium-ion batteries. Learn the definition, measurement methods (DCIR, ACIR), industry standards, and how internal

How to determine the internal resistance of the battery

different battery types along with the required test circuits and calculations. We will cover: Importance of battery internal resistance; Factors affecting internal resis

Battery internal resistance – comprehensive

Mar 20, 2025 · In industries such as electric vehicles and battery energy storage systems, battery internal resistance directly affects overall energy efficiency,

What is Internal Resistance? Definition, Principles, and

Jul 20, 2025 · Discover what internal resistance means in lithium-ion batteries. Learn the definition, measurement methods (DCIR, ACIR), industry standards, and how internal

How to calculate the internal resistance of the battery

What is the internal resistance of a lithium ion battery? The typical internal resistance of a lithium-ion battery varies depending on its capacity and design. Generally,it ranges from a few

6 FAQs about [Battery cabinet battery internal resistance 19 milliohms]

What is the internal resistance of a lithium ion battery?

The typical internal resistance of a lithium-ion battery varies depending on its capacity and design. Generally, it ranges from a few milliohms to tens of milliohms. For example, a 2000 mAh lithium-ion battery may have an internal resistance of around 50-100 mΩ. Can high internal resistance cause a battery to fail?

What is battery internal resistance?

Battery internal resistance refers to the resistance of the battery to the flow of current. It includes the combined resistance of components such as battery materials, electrodes, and electrolytes (find the top 10 lithium ion battery electrolyte manufacturer).

What is ohmic resistance in lithium ion battery?

Ohmic Resistance Lithium Ion Battery internal resistance encompasses various elements hindering the current flow within the battery. Ohmic resistance, a fundamental component, represents the inherent opposition within the battery’s components.

What is the internal resistance of a lithium ion 18650 battery?

Typically, it ranges from a few milliohms (mΩ) to tens of milliohms. What is the internal resistance of a lithium-ion 18650 battery? The internal resistance of a lithium-ion 18650 battery may vary based on the specific model, age, and condition. Generally, it can range from around 20 to 80 milliohms (mΩ) for these types of batteries.

What is a good internal resistance for a LiFePO4 battery?

A good internal resistance for a LiFePO4 (lithium iron phosphate) battery is typically lower than other lithium chemistries. Depending on the specific battery model and condition, it may range from around 2 to 20 milliohms (mΩ). Lower internal resistance often indicates better Performance and efficiency.

How to measure battery internal resistance?

The battery internal resistance is usually measured in milliohms (mΩ), and measurement methods include AC impedance measurement (EIS), DC voltage drop method, LCR meter test, etc. Ohmic resistance: determined by the electrodes, electrolyte, conductive materials, etc. inside the battery, mainly affecting the instantaneous voltage drop.

Learn More

- Battery cabinet earthquake resistance

- What is the internal current of the battery cabinet

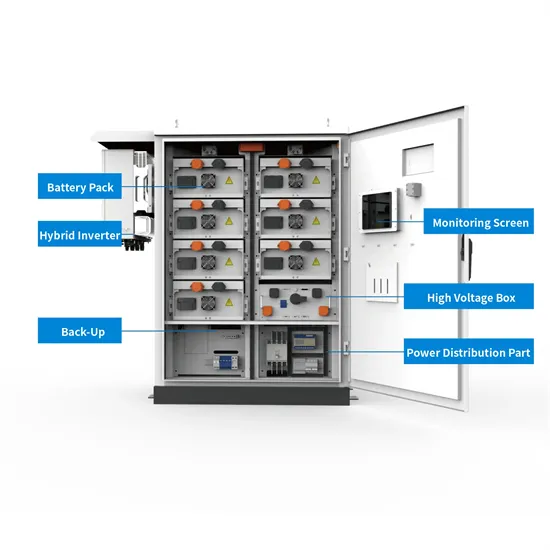

- The internal structure of the battery in the energy storage cabinet and the station cabinet

- Site Energy Battery Cabinet in Vanuatu

- Lithium Battery Site Cabinet Requirements

- Control Unit and Battery Cabinet

- Tonga Battery New Energy Battery Cabinet

- How long is the shelf life of the battery in the energy storage cabinet

- Communication power supply supporting battery cabinet

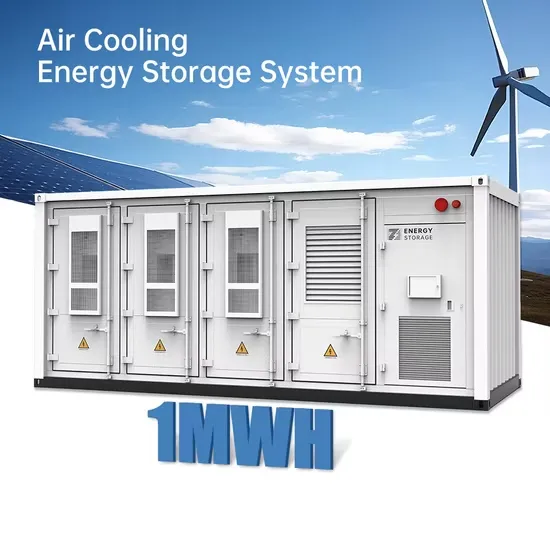

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.