Communication Protocol Reference Guide

Sep 12, 2023 · The Nuvation BMSTM is an enterprise-grade battery management system with support for various external communication protocols like Modbus RTU, Modbus TCP, and

The Complete Guide to Li-ion Battery Pack Communication:

In lithium-ion battery packs, the CAN bus is primarily used for communication between the Battery Management System (BMS) and vehicle control units (VCUs) or charging devices. The CAN

Protocol for Lithium Battery Pack Modbus Protocol

Nov 21, 2023 · The master node is the host in the communication process. The information exchange is done by a question-and-answer method. The information and parameters of the

One-Stop Development and Customization of Communication Lithium Battery

May 6, 2025 · One-Stop Development and Customization of Communication Lithium Battery Pack for Medical Equipment, Find Details and Price about Lithium Battery with BMS 18650 Battery

VOLTA LITHIUM BATTERY With Multiple Brands Inverter

Jul 19, 2023 · VOLTA lithium battery CAN/RS485 Communication Cable Order (sequence) Instruction d by setting the dialing switch on BMS to avoid setting the sam

The Complete Guide to Li-ion Battery Pack Communication

Jun 16, 2025 · This article takes you deep into the communication world of battery packs, revealing how batteries "communicate" with devices in different scenarios and how to choose

25.9v lithium ion battery pack 30Ah INR21700-7S6P for AI

Lithium polymer battery cell manufacturing, with 1000+ existing cell models. Cylindrical Lithium ion battery cell manufacturing, with model of 18650, 26650, 14500, 32650, 38120. Battery

Battery configuration dependence to power line communication

Feb 15, 2024 · To mitigate these disadvantages in BEVs, the established literature demonstrates improvements to energy storage systems, such as fast charging techniques, improved battery

Protocol for Lithium Battery Pack Modbus Protocol

Nov 21, 2023 · Profile 1.1 Instruction The document stipulates the protocol for command control and data exchange between the lithium battery (slave node) and the monitoring module

Communication within Battery Management system (BMS)

Sep 22, 2021 · Through communication BMS is responsible for optimising the performance of the battery pack. Lithium-ion batteries perform best when their State of Charge (SOC) is

How to choose CAN RS232 and RS485 communication for

Jul 16, 2024 · Whether it is CAN or RS485 communication, both are for information exchange between battery packs, but they also have different baud rates, transmission speeds and

Electric Scooter Battery, 36V 7800mah Quick

Oct 17, 2024 · About this item 【Stable Performance】The Battery Pack Scooter Stable performance, great power and reliable quality. Charging time is about 5

Lithium battery BMS communication

Jun 2, 2025 · The communication between a Battery Management System and inverter is not merely an ancillary function; it is a central pillar of efficient energy management in lithium

6 FAQs about [Communication lithium battery pack]

What is a lithium-ion battery pack?

Lithium-Ion battery packs are the preferred power solution for today’s portable equipment. Portable device applications typically require the inclusion of power interaction functionality more than ever before.

What is a cell-con smart battery pack?

Cell-Con will provide a custom Lithium-Ion smart battery pack solution that utilizes SMBus / CANbus / I2C for communications between the battery, host device, and charger. Smart battery assemblies include an electronic circuit with a microprocessor to provide fuel gauging functionality (available run time / capacity).

How does RS485 work in lithium batteries?

Each battery cell has its RS485 transceiver that facilitates bidirectional communication with neighboring cells and the BMS. This enables real-time data transmission and ensures that the BMS can accurately monitor and manage the entire battery pack. Why Do You Need RS485 in Lithium Batteries?

What is a cell-con battery pack / CANbus / I2C?

Portable device applications typically require the inclusion of power interaction functionality more than ever before. Cell-Con will provide a custom Lithium-Ion smart battery pack solution that utilizes SMBus / CANbus / I2C for communications between the battery, host device, and charger.

What information is included in a smart pack?

Data such as cycle count, usage patterns, battery ID, battery type, serial number, date of manufacture, and other useful information are all integral to the smart pack. Additional customization can be incorporated onto the same board as the battery management to streamline the assembly.

Why should energy storage battery systems use CAN protocol?

1. High reliability and real-time performance: Energy storage battery systems usually require real-time monitoring and control to ensure safety and performance. The CAN protocol has optimized conflict detection and fault tolerance mechanisms, which can provide high reliability and real-time data transmission. 2.

Learn More

- Base station lithium iron battery pack communication

- Communication lithium battery pack

- How much does the Dakar lithium battery pack cost

- Congo lithium battery pack manufacturer

- How much does a lithium battery pack cost per kilowatt-hour

- Specialized in 60v lithium battery pack for electric tools

- Bissau lithium battery pack price

- Huawei Eastern Europe pack lithium battery

- Which is the best lithium battery pack for flashlight

Industrial & Commercial Energy Storage Market Growth

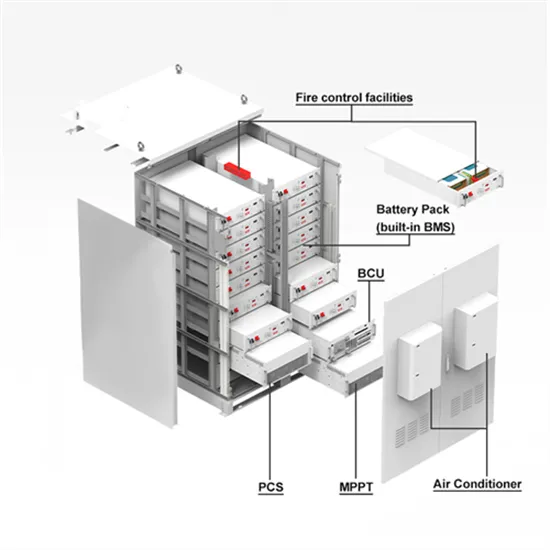

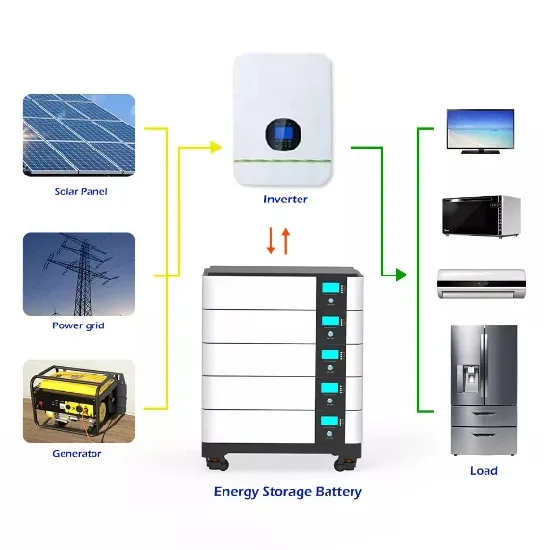

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.