The problem of flywheel energy storage

Flywheel energy storage The main components of a typical flywheel. A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator.The flywheel

Flywheel-lithium battery hybrid energy storage

Sep 2, 2020 · A hybrid energy storage system combining lithium-ion batteries with mechanical energy storage in the form of flywheels has gone into operation in

Bhutan s new energy storage technology

In the near future, the proposed technology can lead to cost-efficient and longer-lasting energy storage devices. This would help reduce carbon emissions and support renewable energy

Thimphu Power Storage: Bhutan''s Answer to Renewable Energy

With hydropower providing 80% of its electricity, Thimphu''s facing a modern dilemma: how to store surplus monsoon energy for dry winters. The Thimphu Power Storage initiative, launched

Concrete flywheel storage system for residential

Jun 21, 2021 · A French start-up has developed a concrete flywheel to store solar energy in an innovative way. Currently being tested in France, the storage

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Technical Feasibility Study of Utility Microgrid Pilot Project at

Aug 12, 2024 · This paper presents the optimization of a 10 MW solar/wind/diesel power generation system with a battery energy storage system (BESS) for one feeder of the

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

Thimphu Power Storage: Bhutan''s Answer to Renewable Energy

You know, Bhutan''s capital isn''t just about dzongs and chili peppers anymore. With hydropower providing 80% of its electricity, Thimphu''s facing a modern dilemma: how to store surplus

Bhutan Flywheel Energy Storage System Market (2024-2030

Bhutan Flywheel Energy Storage System Industry Life Cycle Historical Data and Forecast of Bhutan Flywheel Energy Storage System Market Revenues & Volume By Application for the

The Flywheel Energy Storage System: An Effective Solution

Mar 7, 2020 · Today the role of electricity is very important because it must meet the need for continuous power supply for all manufacturing industries and human social life. Moreover, the

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Botswana, Bhutan, and Qinghe Energy Storage: Pioneers in

Oct 28, 2021 · That''s where energy storage systems (ESS) come in – the unsung heroes keeping lights on and factories humming. With the global energy storage market booming at $33 billion

Botswana, Bhutan, and Qinghe Energy Storage: Pioneers in

Oct 28, 2021 · With the global energy storage market booming at $33 billion annually [1], countries like Botswana, Bhutan, and China''s Qinghe region are rewriting the rules of power

Bhutan Offshore Energy Storage Market (2025-2031)

Market Forecast By Type (Lithium-Ion Batteries, Hydrogen Storage, Flywheel Energy Storage, Compressed Air Energy Storage), By Application Area (Wind Energy Storage, Offshore

World''s Largest Flywheel Energy Storage System

May 17, 2020 · Since there is very little friction, the flywheel spins continually with very little added energy input needed. Energy can then be drawn from the

6 FAQs about [Bhutan Flywheel Energy Storage]

What is a flywheel energy storage system?

Flywheel energy storage systems have gained increased popularity as a method of environmentally friendly energy storage. Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. power delivery system.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

How do fly wheels store energy?

Fly wheels store energy in mechanical rotational energy to be then converted into the required power form when required. Energy storage is a vital component of any power system, as the stored energy can be used to offset inconsistencies in the power delivery system.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

Learn More

- Irish Micro-Controlled Flywheel Energy Storage Company

- Production of energy storage flywheel

- Libya flywheel energy storage system

- FPGA flywheel energy storage

- Sri Lanka small communication base station flywheel energy storage

- Abu Dhabi atz flywheel energy storage

- Maximum flywheel energy storage

- Regulations on the establishment of flywheel energy storage in communication base stations

- Advanced flywheel energy storage system

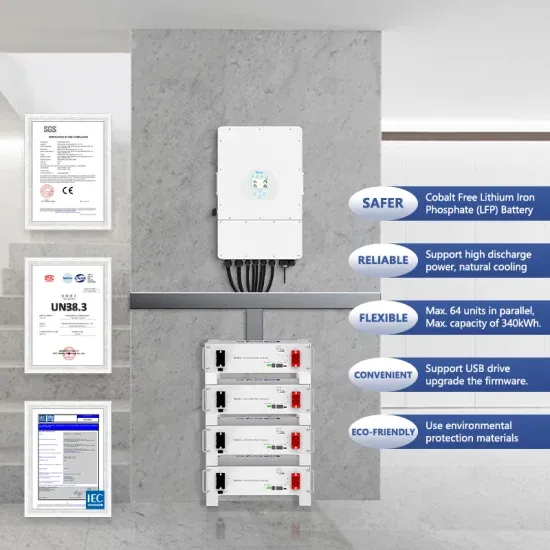

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing explosive growth, with demand increasing by over 250% in the past two years. Containerized energy storage solutions now account for approximately 45% of all new commercial and industrial storage deployments worldwide. North America leads with 42% market share, driven by corporate sustainability initiatives and tax incentives that reduce total project costs by 18-28%. Europe follows closely with 35% market share, where standardized industrial storage designs have cut installation timelines by 65% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing scale reducing system prices by 20% annually. Emerging markets in Africa and Latin America are adopting industrial storage solutions for peak shaving and backup power, with typical payback periods of 2-4 years. Major commercial projects now deploy clusters of 15+ systems creating storage networks with 80+MWh capacity at costs below $270/kWh for large-scale industrial applications.

Industrial Energy System Innovations & Cost Benefits

Technological advancements are dramatically improving industrial energy storage performance while reducing costs. Next-generation battery management systems maintain optimal operating conditions with 45% less energy consumption, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $85/kWh to $40/kWh since 2023. Smart integration features now allow multiple industrial systems to operate as coordinated energy networks, increasing cost savings by 30% through peak shaving and demand charge management. Safety innovations including multi-stage fire suppression and thermal runaway prevention systems have reduced insurance premiums by 35% for industrial storage projects. New modular designs enable capacity expansion through simple system additions at just $200/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial and industrial projects typically achieving payback in 3-5 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (1-2MWh) starting at $330,000 and large-scale systems (3-6MWh) from $600,000, with volume discounts available for enterprise orders.